The “2500th Pioneer” of KraussMaffei works at Demmel

- Automotive supplier Demmel AG uses KraussMaffei's pioneersClub with digital and personal services

- Anniversary: 2500th user at pioneersClub

- Spare parts recommendations, maintenance agreements & machine documentation, each tailored to the individual machine

- Core competence at Demmel: joining plastic and aluminum for automotive trim parts

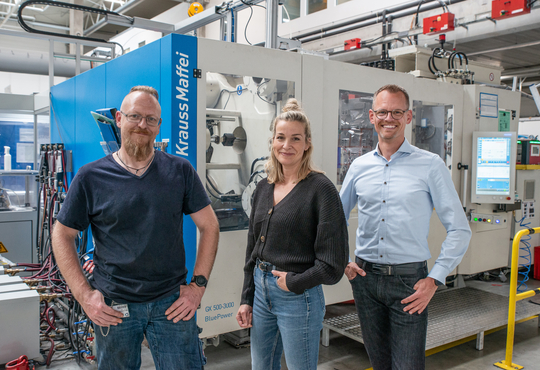

(Parsdorf, 02.07.2025). Star, propeller, spaceship and many more: Demmel manufactures emblems and trim parts for well-known car brands. The company uses machines and services from KraussMaffei - such as the pioneersClub. Horst Zimmermann, production manager at Demmel's site in Heimertingen/Germany, is the 2500th user and is enthusiastic about the platform.

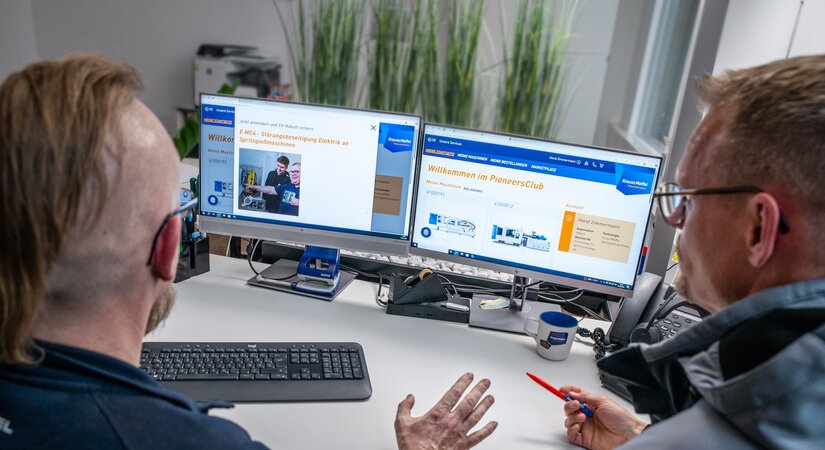

The machine has a special power unit, a drawbar and a particularly heavy-duty sliding door. If you need a spare part, is it the standard version, or do you need a different version? KraussMaffei's pioneersClub makes questions like these superfluous, because each machine is stored via its individual order number and everything that is displayed to the user in terms of service, parts or offers relates exactly to this system. This is particularly helpful if, like Demmel, you also have used machines in production that have been configured by someone else.

Aerodynamic wheel inserts for greater range

The company is a specialist in the combination of plastic and aluminum for automotive trim parts. The Heimertingen site produces vehicle logos for well-known brands as well as aerodynamic wheel inserts that reduce air resistance and increase range (especially in electric vehicles). The mechanically operated BMW rear emblem, which includes a cleaning function for the reversing camera, also comes from here.

For Horst Zimmermann, the pioneersClub is unique in the injection molding world and leaves nothing to be desired - even though he describes himself as a demanding customer. This is another reason why Daniel Bachmann, Product Owner of pioneersClub, welcomes suggestions from users. The platform is intended as a supplement to the human service contacts and always provides their correct contact details. Stefan Betzing, customer consultant at KraussMaffei, knows: “More and more spare parts inquiries and orders are being processed via the pioneersClub. For larger projects, however, customers still prefer to pick up the phone.”

Joint reconditioning of a used GX 500

Sometimes personal contact is essential anyway - such as with the used GX 500 (built in 2014) from Demmel, which spent its first life in an electroplating shop. The aggressive vapors had not only caused the mold mounting platens to rust, but had also caused major damage to the interior. The result was a complex electrical problem. “I kept KraussMaffei's telephone support busy for days on end,” Horst Zimmermann smiles, ”the support was excellent. We all wanted to find the fault together and finally managed to do so.” Thanks to a retrofit, the clamping force could even be increased to 5,500 kN - which is of course also noted in the pioneersClub.

Around 60 colleagues work for the success of the Tier 1 company in Memmingen, 750 across Germany and 1500 at the Demmel Group's international locations. So there are sure to be even more users and machines in the pioneersClub soon.

Contact Person

Marketing & Communication Manager Extrusion Technology

Petra Rehmet

Tel +49 5102 86088605

Mail to Petra Rehmet