Sales launch at K 2022: KraussMaffei starts sales of precisionMolding and powerMolding in Europe and North America

- New injection molding machine series deliver high precision and a high performance level with fast availability and short lead times

- Ideally suited for standard applications for TEC and consumer goods, electrical and electronic devices, automotive, logistics and packaging and medical technology

- Live at K: Sustainable applications for the toy and automotive industry

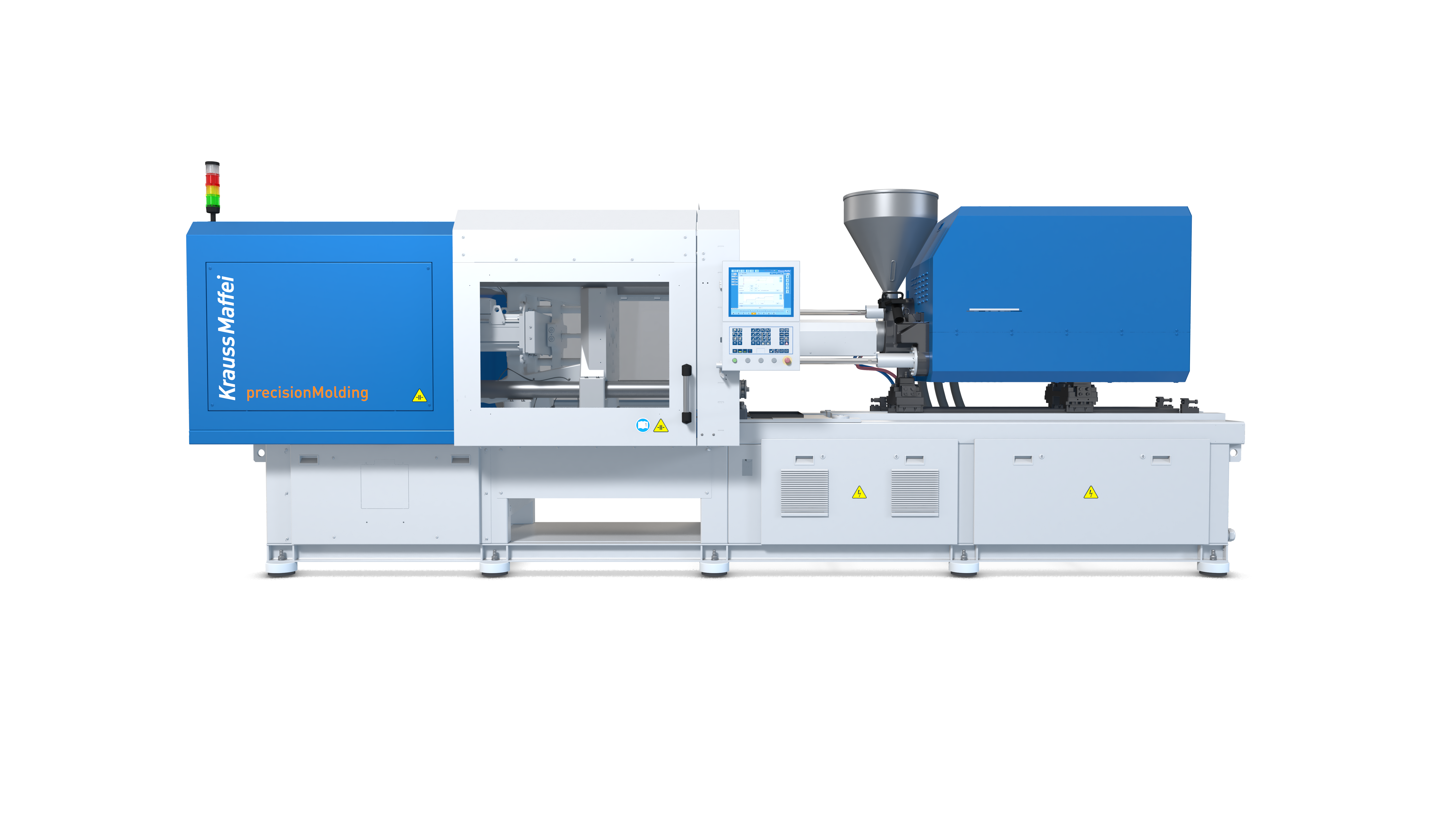

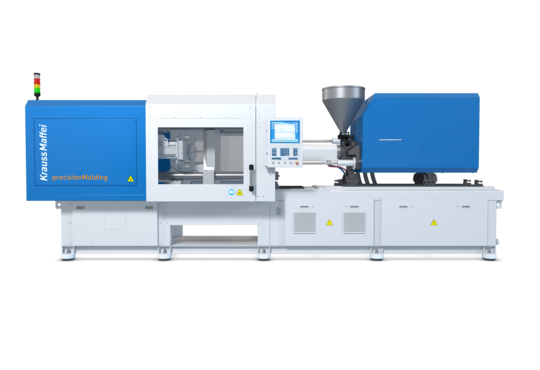

(Munich, October 19, 2022) KraussMaffei is launching sales of the precisionMolding and powerMolding in Europe and North America at K 2022. With this step, the all-electric precisionMolding is available worldwide in the clamping force sizes from 500 to 3,200 kN, while the hydraulic powerMolding two-platen machine will be available from January 1st 2023 worldwide in the clamping force sizes from 6,500 to 16,000 kN. KraussMaffei is expanding its product line substantially by adding two new premium quality injection molding machine series for standard applications.

This development is driven primarily by increasing cost pressure as well as dynamically changing market and product trends. For these requirements, KraussMaffei is now offering two customized solutions in the precisionMolding and powerMolding. Both injection molding machine series feature an outstanding modular concept with a customized selection of options that are available quickly within short lead times. And this is available at an attractive price/performance ratio. The target industries for both the precisionMolding and powerMolding are standard applications, for example for technical parts and consumer goods, electric and electronic devices, as well as for the automotive, the logistics and packaging or the medical industry.

KraussMaffei is undertaking a significant expansion of its product portfolio with the precisionMolding and powerMolding. "We offer our customers system solutions from injection molding technology and automation for the complete range of requirements – from standard one-component injection molding on the precisionMolding or powerMolding to technologically challenging applications on the proven PX, CX, GX or MX series. We have been doing this for many years now with innovative, reliable solutions and worldwide service," Xiaojun Cui explains.

Proven KraussMaffei quality and maximum energy efficiency

Both the precisionMolding and powerMolding stand for high efficiency and profitability that meet the familiar KraussMaffei quality standards. Integration of digital solutions such as the APCplus (Adaptive Process Control) machine function or automation solutions is also easy.

The all-electric precisionMolding inherently features good energy efficiency thanks to the all-electric machine design. The powerMolding offers the proven KraussMaffei BluePower servo drive in standard models. This controls the pumps according to the optimal requirement/energy consumption. Only as much energy as necessary at the moment is consumed. The bottom line: Depending on the application, the powerMolding offers up to as much as 40 percent higher energy efficiency over comparable standard injection molding machines on the market.

Sustainable applications for the toy and automotive industry live at K

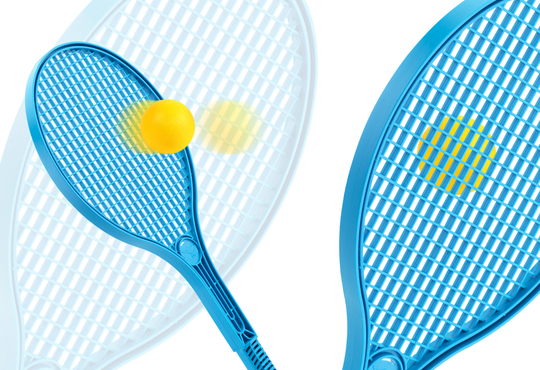

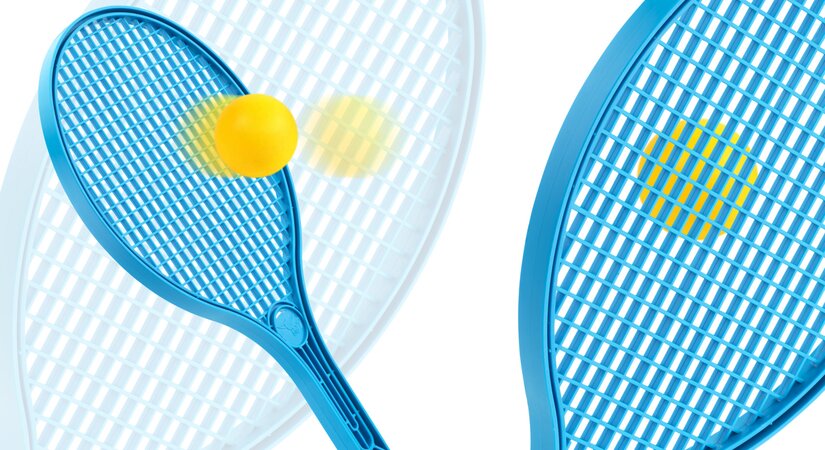

The precisionMolding 160-750 with a clamping force of 1600 kN produces soft tennis ball rackets from a sugar cane-based biopolyethylene from FKUR, which indeed are 100% made of this material. The most outstanding feature: The biopolyethylene from FKUR not only binds CO2 during its own production, but is particularly robust and durable and can be recycled up to 100 percent after use. Here as well, the proven APCplus machine function reliably compensates for external influences on the injection molding process and ensures consistently high component quality. The cost-effective system solution is being supplemented by an LRX EasyControl linear robot that is ideal for simple pick-and-place applications.

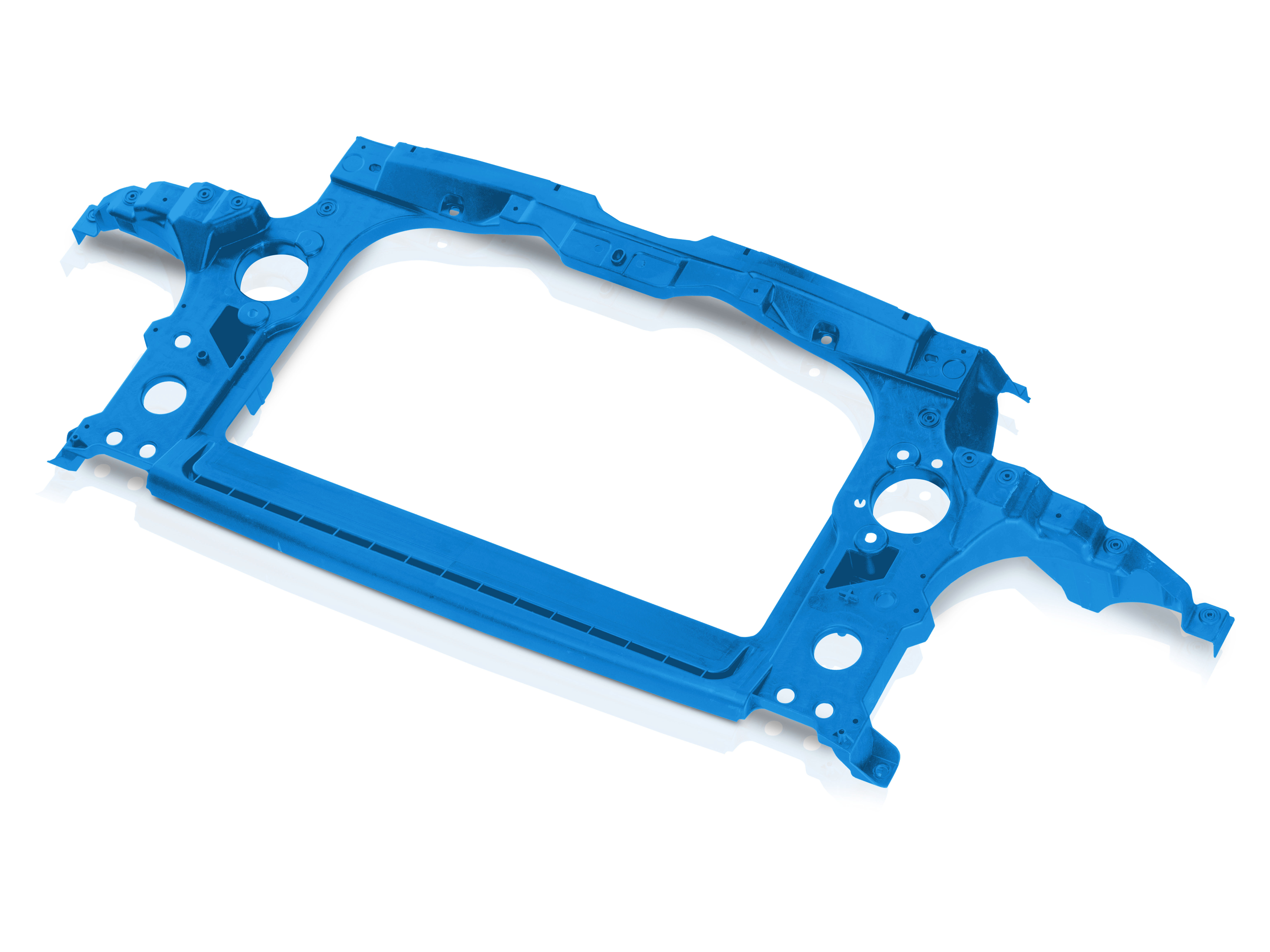

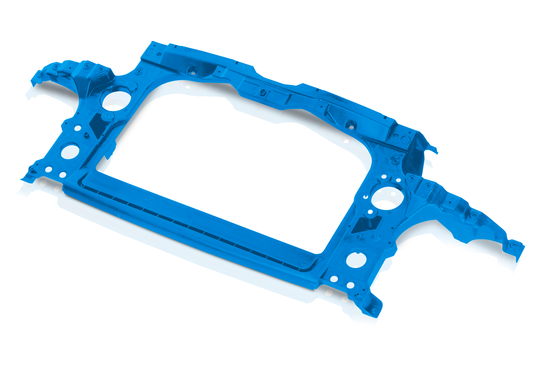

The powerMolding 1300-11900 with a clamping force of 13,000 kN is part of the complete circular economy at the KraussMaffei trade show booth. It is producing frontend carriers for the automotive industry. The material is 100 percent recycled PP made of old insulin pen caps for the medical industry.

For this application on the powerMolding, too, the APCplus machine function assumes an important function. It reliably compensates for the batch fluctuations commonly encountered in recyclate processing and thus ensures consistently high component quality here as well. An integrated linear robot of the LRX series takes over safe and reliable handling of the components.

Contact Person

Marketing & Communication Manager Extrusion Technology

Petra Rehmet

Tel +49 5102 86088605

Mail to Petra Rehmet