Revolutionizing air mobility: FiberForm Technoloy from KraussMaffei speeds up eVTOL production

- Renowned NIAR Institute relies on thermoplastic composite technology for highly complex rib structures

- 3,000 times faster production compared to metal

- Greater design freedom and higher cost efficiency

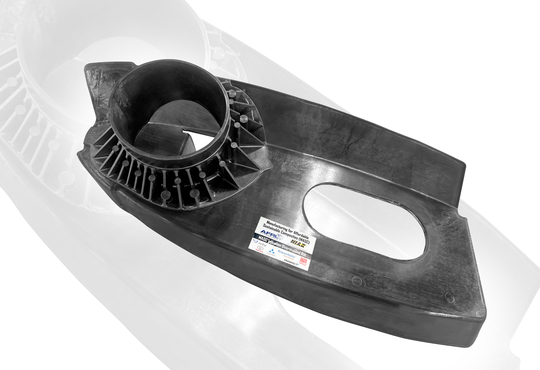

(Parsdorf, Germany/Wichita, USA 09.04.2025) – Together with the National Institute for Aviation Research (NIAR) at Wichita State University, USA, KraussMaffei is driving the advancement of thermoplastic lightweight construction in the aerospace industry. The newly developed structural component with a complex rib structure was specifically designed for eVTOL aircraft, such as air taxis. KraussMaffei’s FiberForm process is used in its production. The result: Manufacturing time is reduced from over 100 hours to just two minutes compared to the metal variant - while maintaining the same strength and safety.

The FiberForm process involves placing an organo sheet - thermoplasticimpregnated continuous fibers - into the mold, forming it, and overmolding it. Compared to conventional metal part manufacturing, this fully automated combination of thermoforming and thermoplastic overmolding offers significant advantages, including lower costs, reduced weight, and a fraction of the production time - all while ensuring the same mechanical strength and safety. At the same time, the FiberForm process allows for significantly greater design freedom.

Driving the advancement of thermoplastic lightweight construction in aerospace: Induwara Herath (Research Engineer, NIAR ATLAS)Eugen Schubert (Sales and Applications Manager, IMM & Automation at KraussMaffei), and Dr. Waruna Seneviratne (Director, NIAR ATLAS) in front of the GXW 450 FiberForm at the NIAR ATLAS lab (from left).

3,000 times faster production compared to metal

The advantages of shorter cycle times become particularly evident with the newly developed rib structure. Traditionally, components of this kind are milled from a solid metal block - a process that removes more than 80% of the material and requires over 100 hours of processing time .“In contrast, the thermoplastic component was formed and overmolded from a flat organo sheet in less than two minutes. The outstanding expertise of the partners involved was crucial to this success,” explains Dr. Waruna Seneviratne, Director of NIAR ATLAS.

In addition to KraussMaffei, the companies Joby Aviation, Toyota, Victrex, and Prospect were also involved in the development. The project is part of the ‘Manufacturing for Affordable Sustainable Composites Program’ by the Air Force Research Laboratory.

Benefiting from automotive mass production

“The results highlight the potential of FiberForm technology, which originates from the automotive industry, for the mass production of primary and secondary structures in aerospace,” Seneviratne continues. Eugen Schubert, Sales and Applications Manager, IMM & Automation at KraussMaffei, emphasizes the importance of the NIAR ATLAS laboratory as an innovation platform: “The NIAR ATLAS Institute provides an ideal environment where machine manufacturers, material suppliers, and tooling developers can collaborate with aircraft manufacturers to test new materials and processes for demanding aerospace applications and develop them for series production.”

Continuing the success story of ‘preighter’

NIAR ATLAS and KraussMaffei have previously worked together successfully in 2024. Back then, the focus was on FiberForm-manufactured window plugs used in the conversion of passenger aircraft into freighters, known as ‘preighter.’ The window plugs were produced in just 90 seconds, were 20 - 30% lighter, and cost half as much as their metal counterparts.

With the new complex rib structure, the development partners are now demonstrating FiberForm technology on a demanding structural component, paving the way for further applications and successful certification in the aerospace industry.

Contact Person

Marketing & Communication Manager Extrusion Technology

Petra Rehmet

Tel +49 5102 86088605

Mail to Petra Rehmet