Lucrative early start – the "synchronous motion" of KraussMaffei Automation

- Gripper starts at the same time as the injection molding process

- Demolding time up to 35 percent lower, cycle time up to 6 percent faster

- Synchronous motion with the ejector means less need for pneumatic systems

Ready, set – already in motion. Normally, the gripper waits for an enable signal from the injection molding machine before it moves into the open mold. With the "synchronous motion" function from KraussMaffei Automation, it starts faster, saving valuable cycle time.

Injection, holding pressure, cooling phase – injection molding is a sequential process with individual steps that are usually optimized. Therefore, they offer little more potential for improving the cycle time. But what about the automation system? Though the proportion of the total process time is less, it is the parts removal that provides leverage for reducing the cycle time in most applications.

Early entry provides valuable time savings

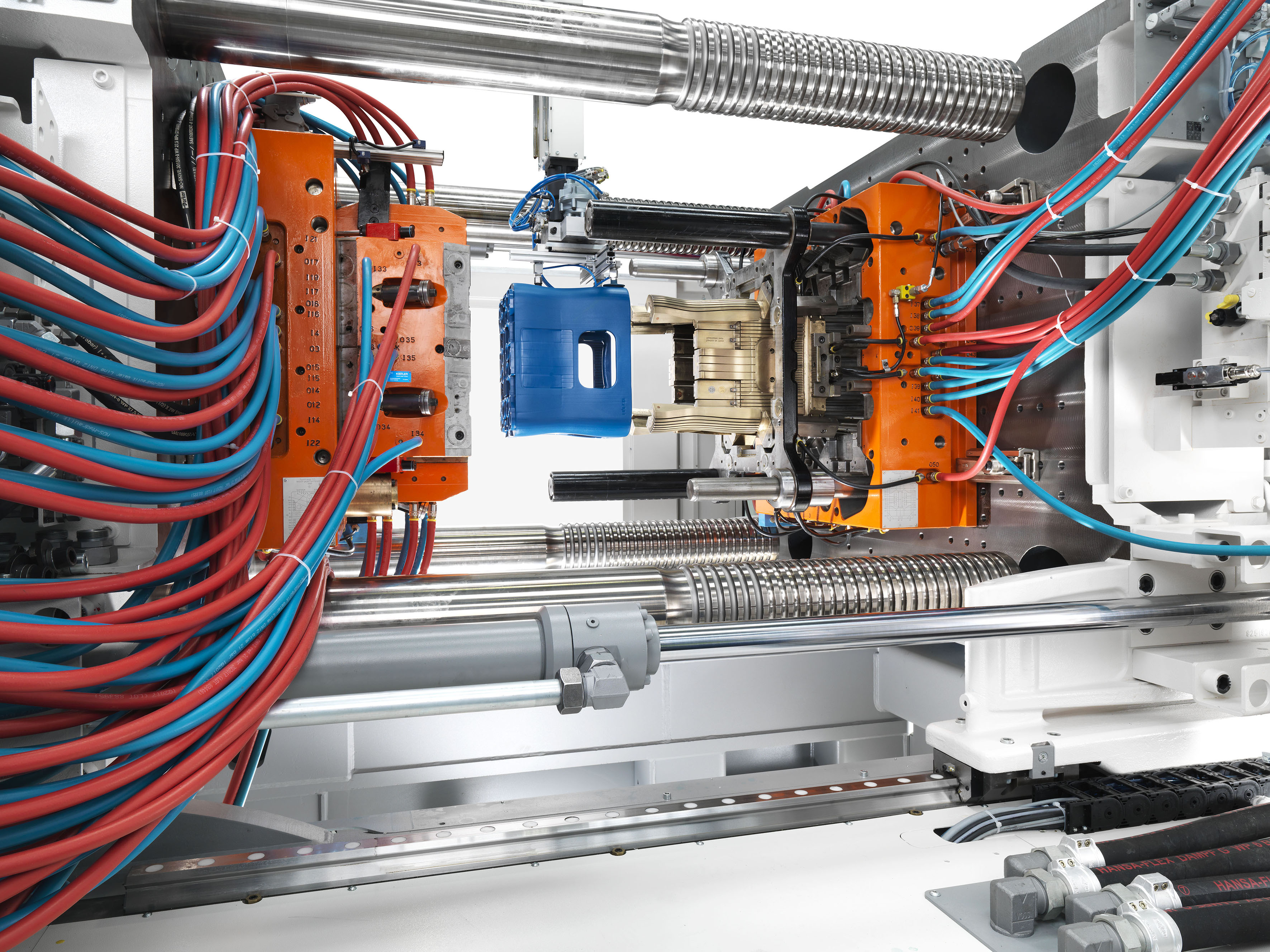

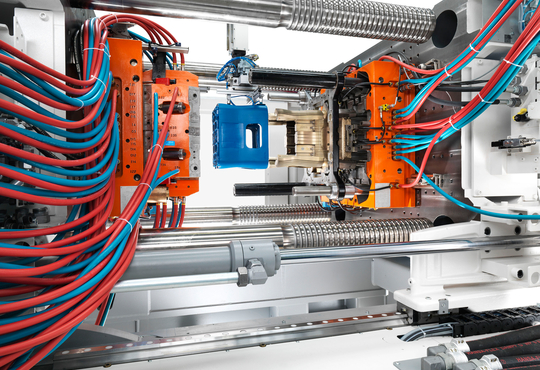

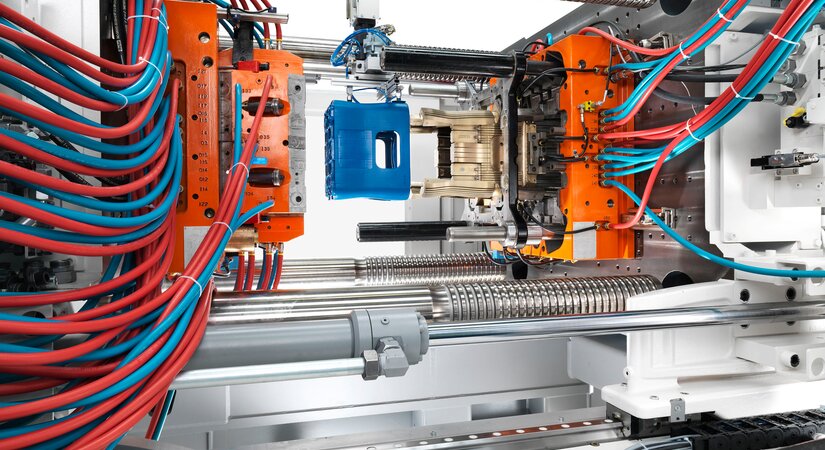

Normally, the robot does not receive the enable signal until the mold is open all the way. The "synchronous motion" function permits early entry of the robot. The robot thus already reaches the removal position of the component during the remaining opening movements. Thus the movements of mold and handling system overlap – saving valuable time.

The goal is to keep nonproductive time as short as possible. To do so, this technology synchronizes component demolding and the opening movement of the machine. Sometimes, this also makes it possible to do away with expensive gripper hardware. After all, the ejector movement is often used for difficult-to-demold parts. This means that the robot grips the finished part during the demolding process and the ejector pushes the component onto the gripper. This requires a costly pneumatic system at the handling (for the "depressurize" step).

However, if the gripper moves along with the ejector, no pneumatic system is required. Depending on the complexity of the application, the synchronization can take place relative to the clamp, part or ejector movement. This lets the customer defines the degree of optimization

35 percent faster demolding time

The synchronous motion enables the demolding time to be reduced by approximately 35 percent. In the production of trash containers, for example, this means a six percent reduction in the complete cycle time – and thus a corresponding increase in total annual volume. The increase in turnover can be up to five percent for pallets and up to four percent for crates.

KraussMaffei offers synchronous motion both for new machines and in the form of an update for the MC6 machine control system for existing machines and complete systems. As a result, the investment pays for itself quickly. Synchronous motion provides its advantages for the linear robots of the LRX series and the IR industrial robots from KraussMaffei. This way, the desired early start pays for itself quickly.

Contact Person

Marketing & Communication Manager Extrusion Technology

Petra Rehmet

Tel +49 5102 86088605

Mail to Petra Rehmet