KraussMaffei revolutionizes glass fiber processing – the new CFP technology

- Noticeable cost advantages with consistent component quality

- ROI in less than a year

- Patented screw geometry for fiber-friendly compounding and maximum efficiency

- Greater formulation flexibility for component-specific applications

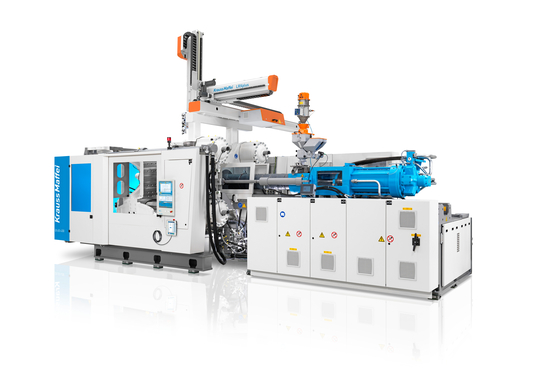

- Live at K 2025: GX 650-4300 with new LRXplus 350 linear robot

(Parsdorf, August 7, 2025) With its new Chopped Fiber Processing (CFP) technology, KraussMaffei is setting a milestone in the processing of fiber-reinforced thermoplastics. This innovative process enables the direct, fiber-friendly compounding of polypropylene (PP) and chopped glass fibers in the injection molding process for the first time. Visitors to K can experience the CFP technology live at the exhibition stand: A GX 650-4300 with the new LRXplus 350 linear robot is producing a complex tailgate component for the automotive industry.

“With the unique CFP technology, we offer our customers a true game changer that significantly reduces their material costs in the production of fiber-reinforced components. We are particularly proud of the heart of the new CFP technology, the patented screw geometry, which was developed specifically for the technology by KraussMaffei,” says Jörg Stech, CEO of KraussMaffei Technologies GmbH.

Technological edge through flexible direct compounding

Compared to traditional processes using pre-compounded long glass fiber granulate, the CFP technology enables separate dosing of PP and glass fibers. Both components can be supplied directly via the machine's conveyor system, homogenized in the cylinder, and processed particularly gently with the help of the new CFP screw. This offers the advantage that no fiber clusters are formed during processing, thus ensuring optimum component properties at significantly lower material costs.

Individually customizable formulations – with cost savings of 30%

The CFP technology enables plastic processors to individually dose and mix polymers and fibers. This allows them to develop their own formulations for components and build up material expertise, giving them a targeted competitive advantage. At the same time, savings in material usage lead to cost reductions of up to 30 percent and a noticeable reduction in the product carbon footprint (PCF) through inline compounding.

ROI in less than 12 months – easy to retrofit

Other highlights of the new CFP technology include compatibility with KraussMaffei machine series and easy retrofitting – even for existing, older systems using the KraussMaffei Retrofit Program. Thanks to the material savings and process advantages that can be achieved, the return on investment (ROI) is less than one year.

Live demonstration at K 2025

Live at K 2025, visitors can experience the CFP technology on a GX 650-4300 (clamping force 6500 kN) with an LRXplus 350 linear robot. The production of a complex, functionally integrated tailgate component with realistic 3D geometry and high functional integration will be demonstrated – without reworking and ready for assembly straight from the machine. This opens up new possibilities for the manufacture of structural and support components as well as reinforcement elements.

In line with the trade fair motto "Performance. Perfected. For You." the GX 650-4300 is equipped with proven BluePower options such as servo drive and insulating sleeves. With BluePower energy and performance monitoring, plastics processors are able to call up precise energy consumption data. In addition, the BluePower ecoAssistant enables the machine to be switched to an energy-efficient mode at the touch of a button while maintaining the same performance.

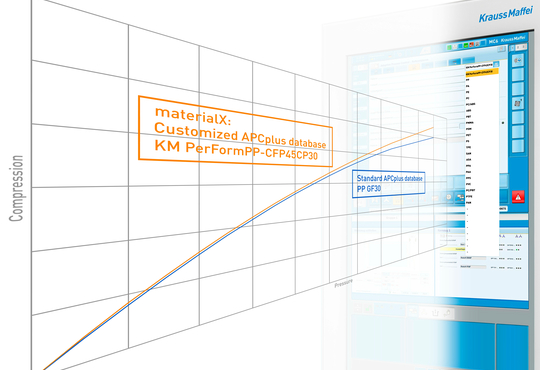

The component is filled in cascade via three injection points. The proven APCplus machine function impresses with new features at K. For example, cascadeX ensures weld line-free filling behavior and improved mechanical properties in applications with cascades. The APCplus function materialX uses material-specific compression curves to control the injection molding process. This achieves a particularly high level of component precision.

Complete process documentation – accessible at any time

The weigh unit integrated into the gripper of the LRXplus 350 determines and records the weight of the components cycle by cycle. All production data and quality characteristics are documented online. Upon removal, all components are given an individual QR code imprint. This enables KraussMaffei to offer plastics processors the option of retrieving the quality characteristics of a component and its production data online at any time, e.g. for quality assurance purposes.

Wide range of applications: from automotive to aviation

Whether in the automotive and aerospace industries or in technical consumer goods, KraussMaffei's new CFP technology offers a high degree of flexibility in the production of structural and load-bearing components as well as reinforcement elements – and that with significant cost advantages.

Partners in the trade fair exhibit are: Borealis Polyolefine GmbH (material), Siebenwurst GmbH & Co. KG (tooling), motan gmbh (material feeding), Audia Plastics s.r.o. (color batch), Helm AG (glass fiber).

Contact Person

Senior Marketing Manager Injection Molding Machinery

Dr. Christina Langbein

Tel +49 172 8529009

Mail to Dr. Christina Langbein