KraussMaffei presents the new BrightStar Electric Press

- Fully electric press with precise temperature control and fast mold change for press lamination and edge folding applications

- Maximum flexibility: Customers can adjust process parameters themselves

- Three press sizes (5, 10, and 20 tons)

- Targeted development of new technologies to support the production of lightweight, high-quality interior soft-touch components in the automotive industry

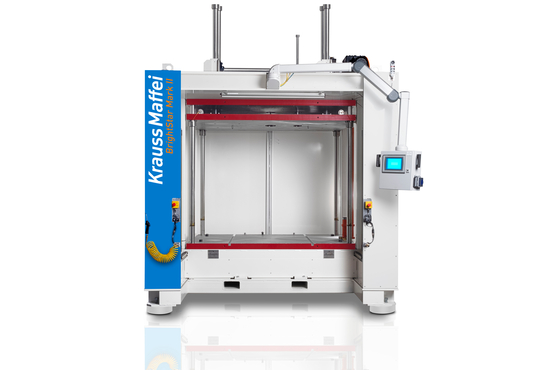

(Parsdorf, October 27, 2025). With the new BrightStar Electric Press, KraussMaffei is expanding its portfolio in the areas of automated press lamination and edge folding technologies. The fully electric press platform impresses with its high precision, ease of use and maximum flexibility – ideal for the production of modern lightweight and soft-touch components in the automotive industry.

The BrightStar was developed specifically for the requirements of press lamination and automatic edge folding applications, but can also be used for combo punch and ultrasonic welding applications. At its heart is the new electric drive in combination with an innovative heating package that enables precise temperature control for heat-based adhesives.

Thanks to the integrated Quick Tool Change option, tools can now be changed even faster and more safely. In addition, customers can make certain changes to the tool program themselves. The new safety features in the main tool sequence program ensure that the tool is reliably protected against damage.

This allows customers to adjust processes immediately and independently without the need for a service technician to be on site. This saves time and increases flexibility in production.

More variants, more possibilities

The new BrightStar Electric Press is available in three variants: 5, 10, and 20 tons of pressing force. It offers a fully modular, customizable platform and allows individual adaptation to customer-specific processes and automation concepts. Thanks to an integrated, high-precision mold set in the upper plate area, no additional tool guidance is required—a decisive advantage for process reliability and repeatability.

The model supports a wide range of technologies such as press lamination, edge folding, sonic welding, IR welding, light punching, and skin trimming.

Practical innovation

Technological advancement

In addition to the BrightStar Electric Press, there is also the BrightStar Lite. It is the latest generation of the proven BrightStar Electric Press line and is available in a 5-ton version.

This is a more cost-effective option for low tonnage applications compared to the regular BrightStar. The mold space of the BrightStar Lite has been expanded from 1,700 mm to 2,500 mm, while design optimizations reduce the overall weight – with the same stability and precision.

The comprehensive expertise of the KraussMaffei team from all phases of the tool life cycle – from conception to design and manufacturing to commissioning – has been directly incorporated into the development of the new BrightStar and BrightStar Lite.

Contact Person