KraussMaffei at the Swiss Plastics Expo: Maximum precision and performance during injection molding of pipette tips for medical technology

- All-electric PX 81-180 produces pipette tips in a mold with 32 cavities

- APCplus ensures high process transparency and component quality

- Integrated mold cooling saves valuable energy and improves energy efficiency considerably

(Munich, December 14, 2022) Sensitive products in medical technology require a high degree of purity and quality from the injection molding process. At the same time, processors face the economic challenge of minimizing the costs per part. At the SwissPlastics Expo in Lucerne (January 17 – 19, 2023) KraussMaffei demonstrates how both work using the example of pipette tips on an all-electric PX 81-180 Medical. The APCplus machine feature ensures consistently high process transparency and component quality.

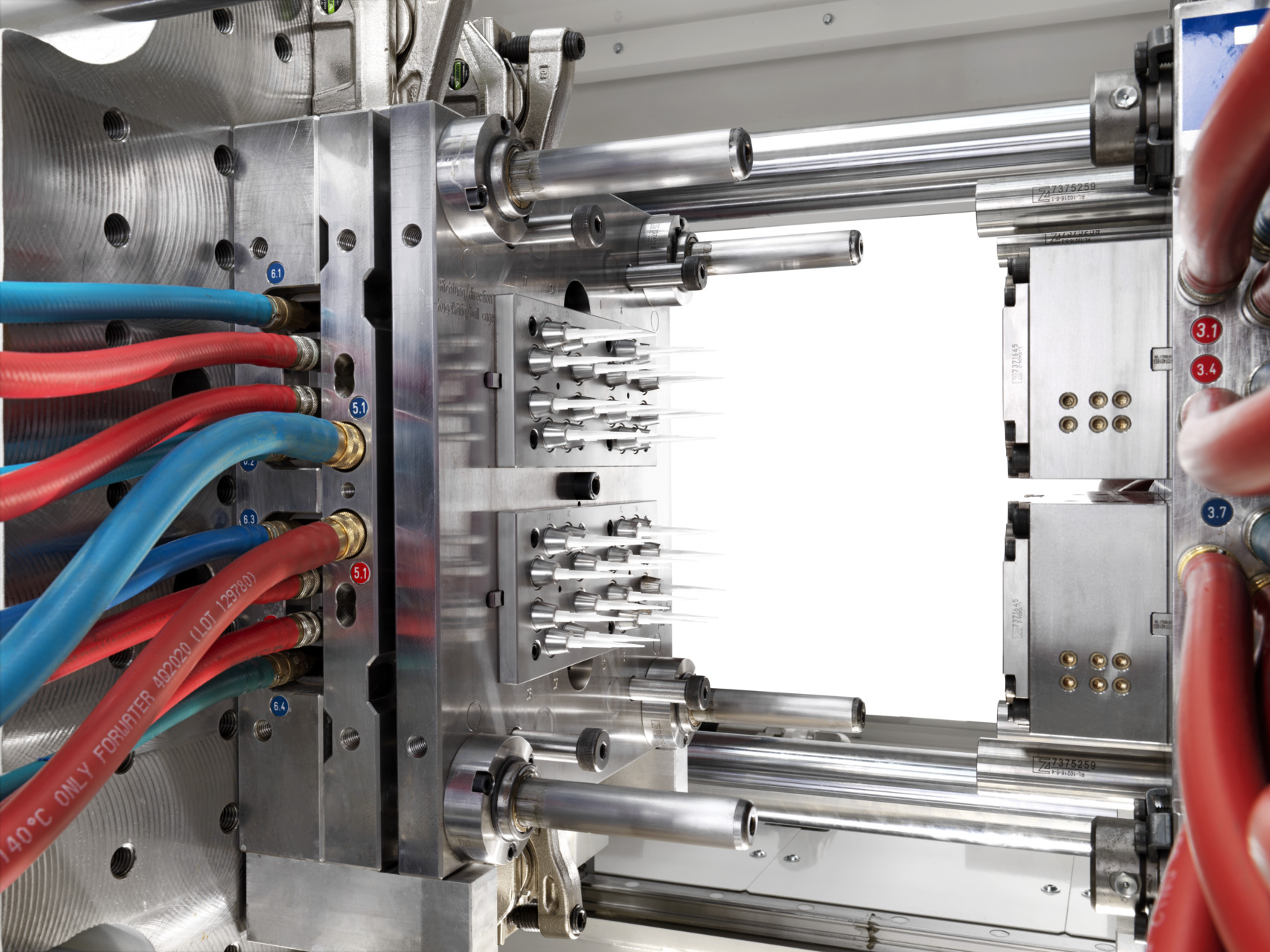

"The need for diagnostics products such as pipette tips, PCR platens and petri dishes has risen sharply, also in Switzerland, in the course of the COVID-19 pandemic. During production there is a demand not only for the highest quality and purity standards, but also for very high production quantities with the best energy efficiency. With the all-electric PX series, we combine maximum precision with top performance and offer our customers an optimal solution", explains Bruno Schleiss, Managing Director of Krauss-Maffei (Schweiz) AG. The all-electric PX 81-180 Medical with a clamping force of 800 kN produces pipette tips with a component weight of 0.22 g at the Swiss Plastics Expo. The cycle time with the 32-cavity mold is 7 seconds.

The PX 81-180 Medical has been designed specially for the requirements in the cleanroom up to cleanroom class ISO 5. This includes encapsulated drive units, antistatic painting and raised machine legs to FDA-compliant hydraulic fluid.

Top quality with the shortest cycle times

The PX 81-180 Medical is also equipped with some performance options in order to meet the high requirements in the production of pipette tips. This includes, e.g., the sharply increased injection speed of 450mm/s, which is required for high quality and precise filling of the pipette tips. The reinforced drive for plasticizing guarantees the shortest cycle times. An all-electric ejector with higher speed also ensures a clean and consistent take-out automation of the components.

Every part is a good part with APCplus

Digital solutions for process enhancement and for collecting and evaluating data round off the offering of the PX 81-180 Medical at the Swiss Plastics Expo. The APCplus (Adaptive Process Control) machine feature, for example, ensures a high shot weight consistency and thus consistent component quality. This keeps scrap to a minimum. It cuts down on material as well as costs. The process windows for APCplus are already defined in the validation process for the medical industry.

Best energy efficiency

Sensible use of resources such as material and also energy is more important today than ever before. This also applies to production in medical technology. The PX 81-180 Medical at the KraussMaffei exhibition stand features equipment that make it a perfect fit for saving energy. In addition to the servo design of the hydraulic unit and the recuperation system for recovering brake energy, it features the proven Eco-Pac insulating strips on the injection unit. They stabilize the temperature profile and increase process stability. The heating time is reduced by up to 30 percent.

Even greater energy savings are possible with the Orca mold cooling system from partner Jurke Engineering. The system is fully integrated into the MC6 machine control system. Unlike a conventional water distributor, the system uses ultrasound to measure the flow velocity and quantity. This takes place from the outside and without making contact with the medium. As a result, the Orca distributor block does not have any cross-section narrowing, meaning fewer pressure losses. Energy efficiency is improved, the cycle time drops and the quantity produced per hour is increased.

Partners of KraussMaffei at the trade show exhibit at the Swiss Plastics Expo are Zahoransky, Motan Colortronic, Borealis, and Jurke Engineering.

KraussMaffei at the Swiss Plastics Expo

Hall 2, Stand D2101

Contact Person

Marketing & Communication Manager Extrusion Technology

Petra Rehmet

Tel +49 5102 86088605

Mail to Petra Rehmet