KraussMaffei at K 2025: PUre synergy effects - reaction technology with injection molding and extrusion

- ColorForm for headlights: Thermoplastic plus PU surface and foil decoration

- purity glycoLine PU: Recycling PU on an industrial scale - circular economy together with extrusion

- RimStar dosing machine series continues on the path to digitalization

(Düsseldorf/Parsdorf, June 16th 2025) More knowledge creates more interesting solutions: With ColorForm and purity glycoLine PU, KraussMaffei is presenting two applications at K 2025 in Düsseldorf (October 8th – 16th) in which polyurethane processing from the Reaction Process Machinery division (RPM) cooperates with injection molding technology and extrusion respectively. The goal is process reliability and sustainable value creation. KraussMaffei is the only company that can supply machines and processes for the entire polymer processing chain from a single source.

The environmental regulations for spray painting are constantly becoming stricter and are causing a boom elsewhere. ColorForm, the painting of thermoplastic components using PU flooding, is experiencing a steep rise around 15 years after its development.

At K 2025, KraussMaffei and its partner Leonhard Kurz are taking technology integration even further and combining ColorForm with a film decoration system for which a new type of mold-integrated film thermoforming concept has been developed.

The application can be seen live on a GXW 650 (with swivel plate) at the Leonhard Kurz booth (Hall 5 / A19). The innovative 3K demonstrator component, based on a headlight (length 720 millimetres), was designed in such a way that the design film provided by Leonhard Kurz is back-injected with a crystal-clear and a black polycarbonate using the in-mold labeling process.

As PC would yellow due to UV radiation and headlights are exposed to stone chips and similar stresses, the component is given its crystal-clear polyurethane coating directly in the mold.

Paint layer accurate to a tenth of a millimeter

Ready-painted straight from the injection mold: the ColorForm process gives thermoplastic components a PU coating. This can be adjusted in terms of color and feel - and is also self-healing if desired.

The complete system from KraussMaffei combines reaction process machinery and injection molding technology.

With ColorForm, the PU lacquer layers can be precisely adjusted in the tenth of a millimetre range. A range of different effect and lacquer colors are available, which, in combination with variable haptics, enable a variety of design options.

In addition to protection against chemical influences, a self-healing effect is also possible - for example in the case of fine scratches on the surface. Another visual advantage is the characteristic depth effect that ColorForm creates.

The metering machines manufactured by KraussMaffei enable output rates of up to 500 g/s and are therefore also ideally suited for large-format components.

Suitable metering units are available for adding color, so that even demanding design requirements in the vehicle interior or on the vehicle exterior can be precisely implemented.

KraussMaffei supplies all the components of ColorForm technology as a turnkey solution from a single source - from the injection molding machine and PUR metering technology to fully integrated automation.

Industrial recycling of PU with a high proportion of foreign matter

Sustainable cycle thanks to purity gycoLine PU: The PU components of items such as refrigerators are converted into polyol with recycled content (rPolyol) at the end of their service life using an extruder in a continuous chemical process.

This serves as a starting material for new applications and can be processed in the metering machine without any adjustments.

PU is also frequently used for insulating applications such as refrigerators, and at the end of the appliances' life, the question of disposal arises. Until now, PU from old refrigerators has often been incinerated, for example to generate energy in cement production, but it is foreseeable that the thermal recycling of plastics will be more restricted in the near future.

KraussMaffei is therefore in the process of industrializing a process for the continuous chemical recycling of PU through depolymerization. The project partners are BASF, Rampf (Producer of sustainable recycled polyols) and Remondis (processing and recycling of old electrical appliances).

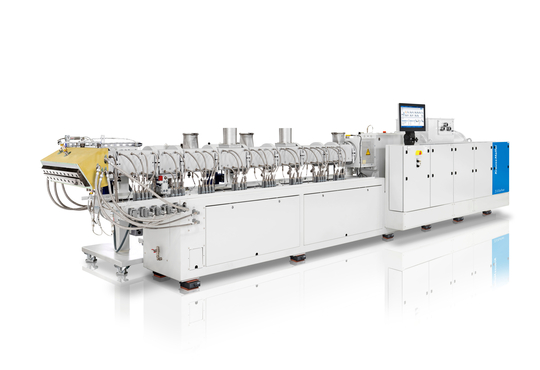

In the purity glycoLine PU process, PU insulating foam from the Remondis refrigerator recycling plant is recycled within minutes using a co-rotating twin-screw extruder (ZE BluePower). Unlike the widely known batch process, this continuous extrusion method can efficiently handle PU regrind with contamination levels of up to 30 %, including residues of other plastics and metals.

In order to achieve depolymerization using a glycolysis process modified by RAMPF, the PUR regrind is mixed with depolymerization agents and other additives in the extruder. KraussMaffei has adapted the filtration technology required for this to the market requirements for polyols in extensive tests at its Innovation Center.

The polyols obtained from the extruder can be used at BASF as a component of innovative PU systems for the production of rigid foams with recycled content. What is particularly important here is that the process is already economically attractive today.

Metering machine ready for digitalization and autonomous operation

At the K trade fair, visitors to the KraussMaffei booth can experience live how the PU system with recyclate content is processed into foamed insulators for beverages.

The Reaction Process Machinery team will be presenting another market launch: a RimStar series metering machine with numerous new features in preparation for digitalization and autonomous operation.

This will make the machine and process even easier to control, even for less experienced users - in future, it should even be possible to completely relieve operators of certain tasks.

Digital analysis tools such as the dataXplorer, which records and evaluates all relevant process data, are already integrated for this purpose. In future, its results will serve as the basis for automatic adjustments during the production process.

Contact Person

Marketing & Communication Manager Extrusion Technology

Petra Rehmet

Tel +49 5102 86088605

Mail to Petra Rehmet