Highly efficient and flexible extrusion solutions at K 2022 in Düsseldorf

- ColorAdjust for the most exacting quality standards in plastics dyeing

- Operator-independent and consistently high productivity and quality

- New ZE-BluePower size gives maximum productivity

- KraussMaffei offers groundbreaking technology for the production of PO floor coverings

- At K 2022 (hall 15, booth C 24 to D 24), trade show visitors will get a live experience of the latest KraussMaffei innovations

(Hannover, 19 October 2022) At K 2022 in Düsseldorf (hall 15, booth C 24 to D 24), KraussMaffei will demonstrate how extrusion companies can boost their performance. At the exhibition booth in Düsseldorf, innovations will revolve around premium product quality, intelligent machine operation, cost-effective production and new processes for the plastics processing industry. The machine manufacturer will be presenting many of its innovations with a live demonstration of the Circular Economy process. In this process, a twin-screw extruder converts shredded medical caps into a fiber-reinforced recompound of precise coloring.

ColorAdjust for the most exacting quality standards in plastics dyeing

KraussMaffei kicks off K 2022 with far-reaching enhancements to its ColorAdjust color measuring and control system and thus meets the increasing demand for efficient and reliable quality control in plastics dyeing.

“With ColorAdjust, KraussMaffei is providing the market with a spectrally operating measuring system for compounding applications, ” reports Xiaojun Cui, Executive Vice President New Machines at KraussMaffei. “This system is designed not only for contactless monitoring of color variations, but it also detects even the slightest deviations, in which case it triggers instant corrections to restore the color setpoint.” This enables processors to achieve a high level of reproducibility even when processing input materials of varying color spectrum. The color setpoint is rapidly restored when starting the compounding process after a stop as well as in the event of color changes. ColorAdjust thus supports sustainable and highly efficient production of reclaim materials. Start-up scrap and rejects are thus minimized, eliminating disposal requirements. This saves time and money, and – above all – valuable raw materials.

Operator-independent and consistently high productivity and quality

“The shortage of skilled personnel is also affecting the plastics processing sector and companies are finding it increasingly difficult to recruit qualified specialists. That's why KraussMaffei's pioneer processControl focuses on simple and clear operation,” adds Xiaojun Cui.

The core feature of the new user interface are so-called wizards that provide the operator with step-by-step instructions for certain procedures such as starting the production line or shutting it down. Operators receive the right information at exactly the right moment and can additionally store their experiences in the system, so that colleagues will also benefit from them. This will enable even less experienced staff members to control complex extrusion processes. Operating errors are thus reduced, which minimizes standstill periods and optimizes production efficiency.

New ZE BluePower size gives maximum productivity

KraussMaffei is investing heavily in the further development of the ZE BluePower series. At K 2022, it launches a twin-screw extruder size with a screw diameter of 186 mm. This extruder size is mainly aimed at plastics processors with the highest throughputs, who require unparalleled productivity and excellent quality. The modular design enables optimum adaptation to different processes. Typical areas of application include reaction, degassing and compounding as well as recycling processes.

“With the new ZE 186 BluePower we once again underline our technology leadership. Our customers benefit from efficient and proven technology that they can adapt precisely to their individual requirements with a wide range of familiar peripherals from the ZE BluePower series,” emphasizes Xiaojun Cui.

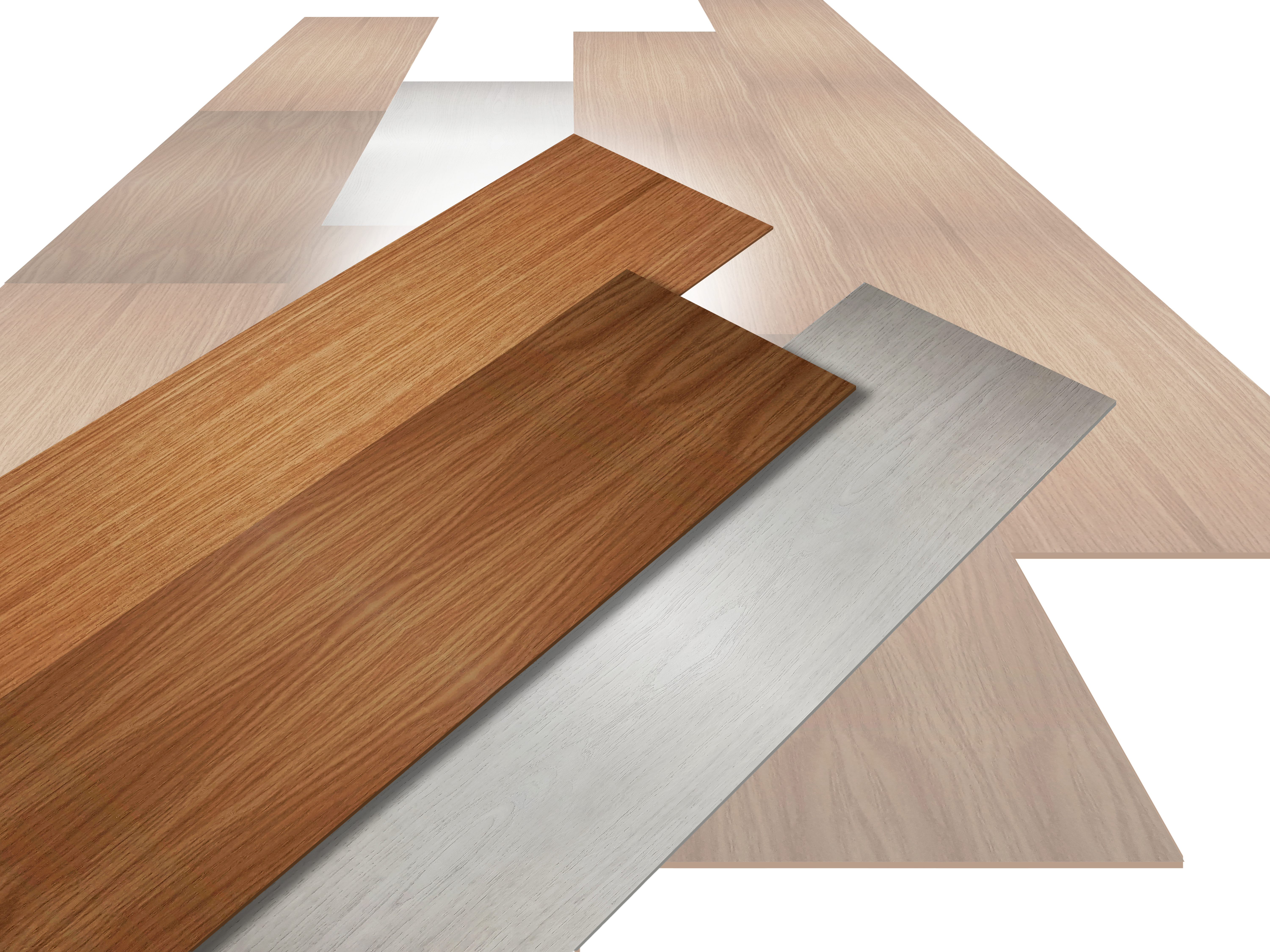

KraussMaffei offers groundbreaking technology for the production of PO floor coverings

KraussMaffei is consistently investing in the “polyolefin floor coverings” growth market. By cooperating with leading raw material manufacturers, the company supplements its technology know-how with an important step in the workflow, i.e. the formulation development. In this way, the machine manufacturer supports its customers in further optimizing their process efficiency and cost-effectiveness.

All in all, KraussMaffei thus offers the complete technology range for highly efficient development and production of PO floor coverings – from formulation development to in-line compounding, shaping and polishing to fully automated lamination, cutting and stacking of the sheets.