High-end closures for luxury brands: Novassu trusts KraussMaffei

- Strategic partnership: Novassu manufactures high-quality cosmetic closures for premium suppliers from chemically recycled plastic on KraussMaffei machines

- CXZ 250/1000-750 Multinject offers maximum flexibility thanks to sandwich and index plate technologies

- Sandwich injection molding with 30% recycled material increases sustainability and design freedom

(Parsdorf/Molinges, 18.11.2025) French closure specialist Novassu manufactures premium closures for brands such as Chanel and Estée Lauder on a CXZ 250/1000-750 Multinject from KraussMaffei. The machine combines 2K sandwich and index plate technologies, enables recycled layers and ensures consistent quality with APCplus. The result is crystal-clear, sustainable closures with 30% recycled content – efficient, flexible, and highly precise.

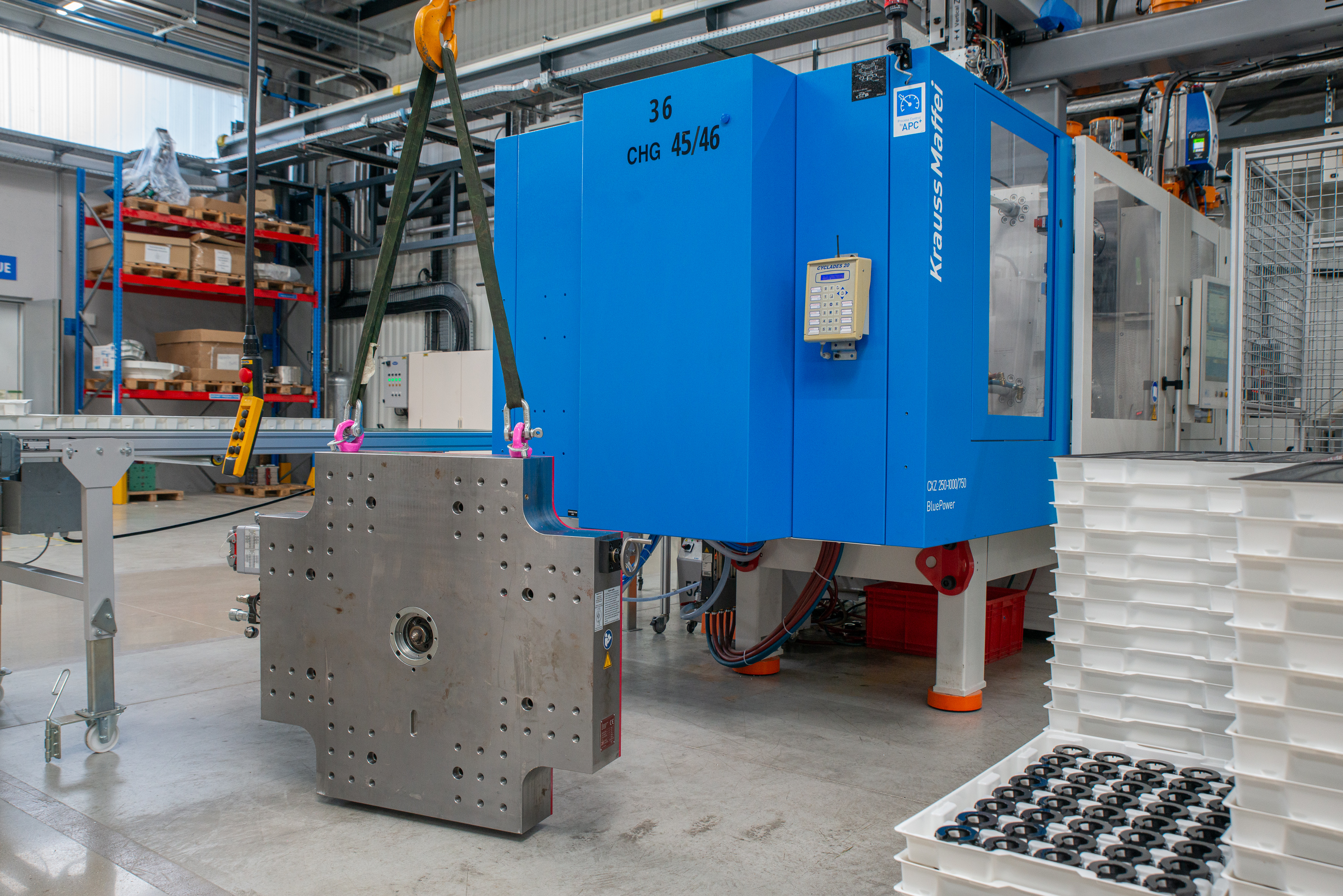

Chanel, Givenchy, Estée Lauder, and Coty – Novassu manufactures all types of closures for the cosmetic lines of luxury brands. The company relies on the CXZ 250/1000-750 Multinject from KraussMaffei for production, which combines 2K sandwich and index plate technology.

The machine has a sandwich plate that offers the possibility to inject a layer of recycling material inside skin material. It is also a flexible solution that allows easy switching between sandwich and standard 2K processes, as well as the use of monomaterial. The index plate allows the cavities to be rotated for overmolding and multilayer processes – a key feature that prompted Novassu to choose KraussMaffei injection molding machines.

Managing Director Gérald Paris emphasizes: “We only invest in machines that offer us maximum flexibility – no off-the-shelf. Our business is continuously evolving, and we need a strategic partner who can also bring in experience from other industries.“

Higher recycled content and greater design freedom

The current project uses sandwich injection molding: recycled material on the inside, new material on the outside. Novassu developed the crystal-clear cube cap itself and, in addition to contract manufacturing, also relies on its own design. The 2K closure contains 30% recycled material. Thanks to the machine's preparation for a third component, other creative effects, such as marbling through multicolor injection, are also conceivable.

At its site in Molinges, Novassu operates around 20 KraussMaffei machines from the CX and PX series (500-4,000 kN). 60 employees use these machines to produce components ranging from 10 to 100 millimeters in size. In addition to pure injection molding, Novassu also offers various finishing steps such as hot stamping.

Change from ionomer to classic thermoplastics

The raw material is crucial for cosmetic products: it must be FDA-certified, which makes the use of recycled materials challenging. Materials such as PET from beverage bottles, however, benefit from good recycling systems. Therefore, it makes sense to use them for parts that do not come into direct contact with perfume or cream.

Novassu is currently shifting from ionomer to classic thermoplastics. Ionomer can only be recycled chemically, whereas mechanically recycling is possible with PET that is hardly contaminated. This change in material also opens up the possibility of using KraussMaffei's all electric PX machines. Since 2019 all machines have been equipped with the APCplus function, which automatically adjusts the switchover point and holding pressure according to the melt viscosity, ensuring a constant shot weight – particularly beneficial for recyclates, which often come in batches with varying properties.

”With APCplus, we’ve significantly reduced scrap and improved our product quality. This is a clear benefit also in terms of cost-efficiency“, adds Gérald Paris, Managing Director of Novassu.

Built for growth

Novassu plans to expand with additional injection molding machines in their new 3,000 m² hall and also wants to continue growing technologically. This is another area where the advantages of the partnership with KraussMaffei play a key role: the proven processes open up new design possibilities for Novassu and thus further areas of growth.

Contact Person

Senior Marketing Manager Injection Molding Machinery

Dr. Christina Langbein

Tel +49 172 8529009

Mail to Dr. Christina Langbein