Greater system flexibility in industrial 3D printing with KraussMaffei

- Scalable manufacturing cell with six-axis robot for additive material extrusion

- Heated vacuum table: 2.0 x 2.5 m

- In-house developed printCore extruder with output rates of up to 70 kg/h

- Processing of a wide range of technical and fiber-reinforced thermoplastics and high-performance polymers

- Modular expandability, e.g. through integration with rotary table or milling cells

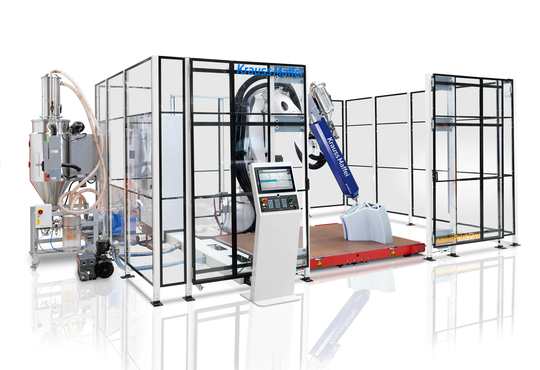

(Parsdorf, October 30, 2025) KraussMaffei is showcasing its powerPrint Flex, a modular 3D printing solution for large-format components and tools, at Formnext (Frankfurt/Main, November 18-21, 2025). Following the success of the closed 3D printing system powerPrint Plus, KraussMaffei is now offering maximum flexibility with robot-based manufacturing cells. The modular powerPrint Flex concept will be on display at Hall 12.1 / Booth E119.

From designer furniture to thin-walled automotive parts and tools for resin transfer molding (RTM) – industrial 3D printing is conquering a growing variety of applications. KraussMaffei’s compact and powerful robotic solution, powerPrint Flex, provides maximum flexibility for these diverse requirements. The system combines KraussMaffei’s proven extrusion technology with a modular architecture, offering manufacturers a high degree of freedom in terms of design and materials. With powerPrint Flex, production cells can be scaled and individually configured to meet specific customer needs.

A thin-walled component in the making

At the KraussMaffei Formnext booth, visitors will be able to see the powerPrint Flex in action as it produces a carbon fibre-reinforced polycarbonate rear diffuser for a sports car. Large-format 3D printing enables the rapid, tool-free production of large, thin-walled components with high rigidity and precision, making it ideal for functional prototypes and design studies. This allows design changes to be implemented immediately, development times to be shortened, and costs to be significantly reduced.

In-house developed extruder: printCore 35-25

The standard configuration of powerPrint Flex includes a Comau N-170 robot within the cell, though various customization options are available. The print bed measures 2500 x 2000 mm, can be heated up to 180 °C, and features 16 vacuum zones for the printing plates. KraussMaffei’s in-house developed extruder, printCore 35-25, enables high output rates from 30 to 70 kg per hour, depending on the material feed system. With a maximum melting temperature of 400 °C, even the most demanding fibre-reinforced thermoplastics and high-performance polymers can be processed. This makes the system suitable for use in the automotive and aerospace industries, as well as for tool manufacturing and general industrial projects.

Flexible integration of the robot into modular manufacturing systems

powerPrint Flex uses the Sinumerik One system from Siemens to control its six-axis robot. This control system enables precise, dynamic and consistently networked motion control. Thanks to its modular design, powerPrint Flex can be integrated into existing manufacturing environments and expanded with additional functions, such as rotary tables or milling centers. The result is a fully developed solution that are optimally tailored to the respective production process.

Hardware, consulting, and services

KraussMaffei’s decades of expertise in several areas of plastics processing form the basis of its additive manufacturing strategy. The company’s systems enable industrialized 3D printing with high precision, consistent quality, and scalable efficiency. Customers benefit from comprehensive technical expertise, solution-oriented consulting, and a global service network. KraussMaffei also helps manufacturers develop their business case and offers support in creating customized additive manufacturing or hybrid production systems.

Contact Person

Marketing Manager Additive Manufacturing & ColorForm

Julia Reich

Tel +49 89 8899-1896

Mail to Julia Reich