Continuous tube die centering for precise wall thickness with maximum material savings

- Time and cost savings in the production of rubber tubes

- Automatic correction of setpoint variations

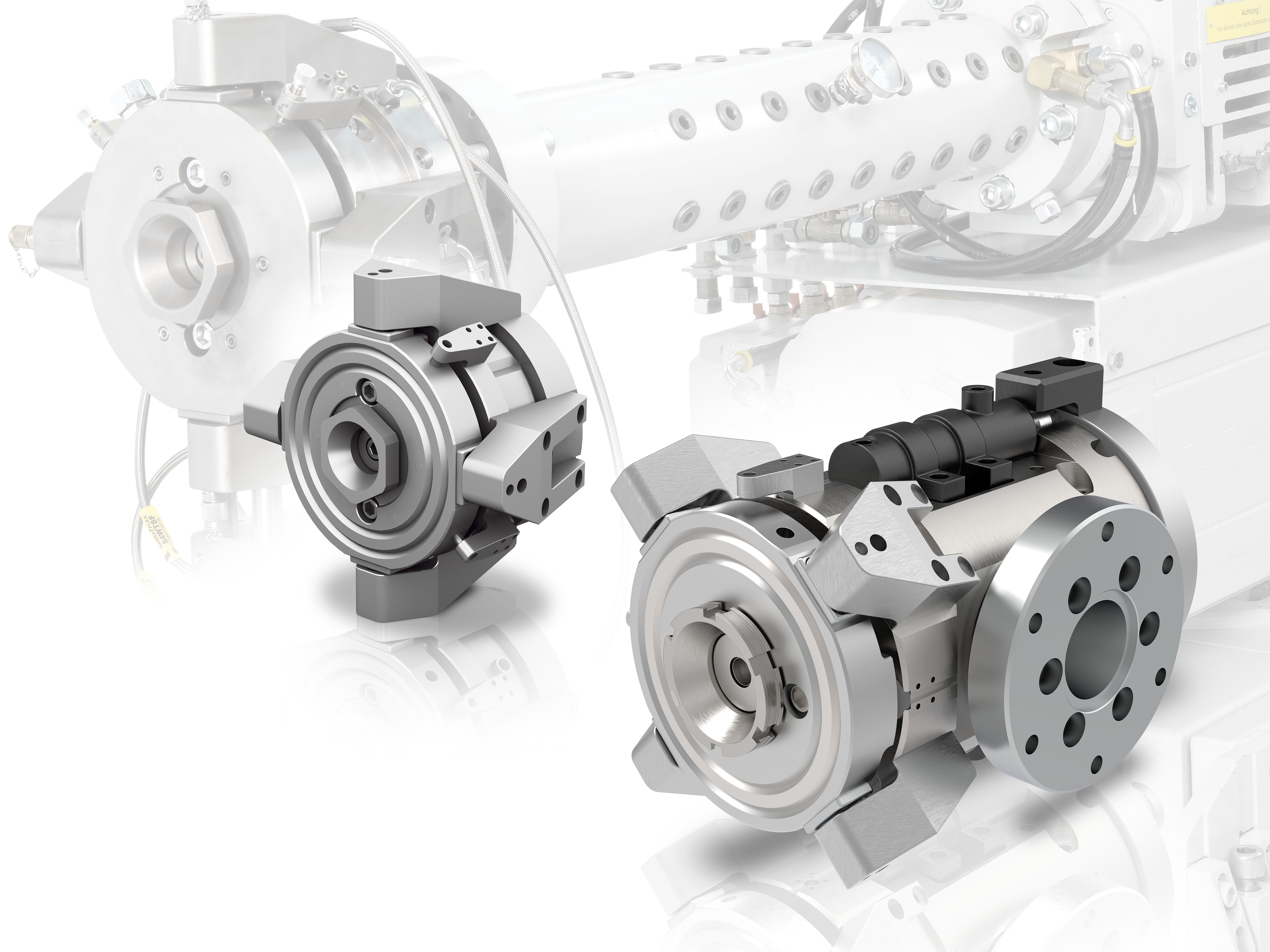

(Hannover, May 19,2022) Exact wall thicknesses are of particular importance in the production of rubber tubes. If the wall thickness is too thin, quality is compromised – but if the wall is too thick, more material is needed in the production process. KraussMaffei’s self-centering tube dies equipped with a wall thickness gauge provide an excellent solution to tackle this problem. They precisely correct any deviations in the ongoing extrusion process. In addition, maximum repeatability is ensured when it comes to frequent batch changes.

Time and cost reduction in the production of rubber tubes

As compared to conventional solutions, customers benefit from substantial material savings when using the self-centering tube dies combined with a wall thickness measuring system. Regardless of the production speed, the system automatically controls and optimizes the hose wall thickness and the concentricity during the extrusion process. The wall thickness tolerance range is thus reduced by 0.05 mm, which ensures material savings of up to 2.5 %. Due to the input material reduction, the investment pays off after just a few weeks in 24/7 production. “Further savings potential can be found in the set-up times of the hose extrusion lines. Instead of wasting time with die changes, adjustments or start-up/shut-down processes, the extruders or extrusion lines equipped with self-centering tube dies reach production mode much faster, which saves time for further operations,” explains Dr. Gerard Nijman, Global Application & Product Owner Tire & Rubber at KraussMaffei.

Automatic correction of setpoint variations

Self-centering tube dies are available for single or multi-layer tubes with or without fabric reinforcement in the diameter range of 3 to 120 mm and suited for different extrusion pressures. Thanks to the automatic adjustment, the floating die inside the extrusion head can be displaced in any required direction. In the event of batch changes, new head parameters are set at the push of a button. Any setpoint deviations in terms of wall thickness and concentricity are immediately corrected and displayed on the control panel. The system stands out for highly professional and reliable production combined with maximum product quality.