40 seconds for two interior doors

- Interior door trim receives map pocket, recessed grip, armrest and more

- 350 milliseconds for camera inspection plus calculation of the exact position

- Assembly tunnel with variant recognition via barcode

(Parsdorf, 10.12.2025) Ready to go straight from the machine – that is the ideal in modern everyday production. Where downstream production steps or rework are required for technical reasons, these must be carried out as efficiently as possible. The KraussMaffei site in Viersen has specialized in this field and offers complex automation solutions. For example, for the assembly of card pockets, recessed handles and more on the door of a manufacturer of original components in the premium segment.

For the customer Yanfeng, a Tier 1 company, the team led by plant manager Marcel Joppen developed an intelligent production concept to complete the interior trim of the car doors as quickly as possible. "In our Trimming Technology Center, we can do almost everything that needs to be done after the actual plastic part has been manufactured," says Marcel Joppen.

"KraussMaffei is an important strategic partner for us. Together, we do everything we can to meet the high requirements of our OEM customers in the best possible way. The plant in Namestovo is currently in a dynamic development phase with great potential for new projects.

In this context, we are relying on the excellent support and trusting cooperation with KraussMaffei to successfully realize all milestones defined by the customer." says Martin Kerestesi, Plant Manager of Yanfeng International Automotive Technology Slovakia at the Namestovo site.

Door panel passes through three assembly stations

The manufacturer of original components in the premium segment now drives the so-called door panel as a basic carrier past three assembly stations. It is screwed twice, and at the third station, the large composite component is fitted with clips, which will later be used to attach it to the actual metal door.

For even greater efficiency, two door panels are placed in an aluminum frame on a self-propelled load carrier, which transports them past the robots positioned on the left and right. On the way into this assembly tunnel, a magnetic stop and barcode scanner are used to query which door variant is involved and which equipment it should have.

As the base carrier is manually clamped to the frame, the position is also checked by camera to ensure that the screws for the five to seven add-on parts are in exactly the right places. The armrest, the recessed grip and the map pocket are mounted in this way.

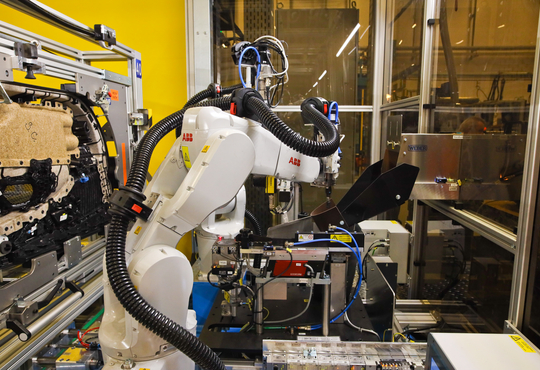

The robots (type ABB 1200-7-70) retrieve the 18 screws per door from a dispenser, as they cannot be blown shut due to their geometry. For this to be possible, the ratio of head to shaft would have to be around 1:1.5 - but here the head is significantly larger. Nevertheless, the speed is high. The cycle time for six screws, including camera measurement, is 24 seconds. Three robots are active per door.

1.4 seconds per clip with rubber seal

The next step of placing the clips is similarly swift. While the trolley is still moving, a robot (type ABB 1600-145-10) removes nine pieces in 13 seconds - using a vacuum gripper with four double pickers and one single picker. A laser sensor then scans the clip positions in nine seconds and measures their depth, as the door panels can be positioned slightly differently on the aluminum frames.

The clips with rubber sealing lips are then positioned in 1.4 seconds per piece, so that the cycle time for the entire process, including camera and laser measurement, is 29 seconds. The camera system itself works in the blink of an eye: 350 milliseconds to capture and evaluate the image, and to calculate translation and rotation.

Including the time for moving the load carrier between the stations and clamping and unclamping the trolley, the cycle time of the assembly line is 40 seconds. A total of eight robots then produce two interior door panels.

Trimming Center for a wide variety of finishing processes

The three stations can be expanded as required if additional process steps need to be implemented. KraussMaffei also offers a wide range of systems for the post-processing of plastic parts, such as punching, milling, deburring, laser cutting, ultrasonic cutting, ultrasonic welding, flame treatment or scoring.

The latter refers to a cold knife cut that is used, for example, to deliberately weaken the material at the location of the airbag so that it clears the way for the airbag in the event of an accident. The Trimming Technology Center has been dedicated to tasks such as these since 2005 and now has over 75 employees.

All automation systems are 100% tailored to the respective project and individually developed. By far the largest share goes to the automotive industry, but the expertise from Viersen is also becoming increasingly interesting for customers from the medical technology sector.

Contact Person