100% recycled material – 100% quality: New 3-layer PVC pipe head from KraussMaffei Extrusion

- New patent-pending flow system

- Reliable processing of up to 100% recycled material in all three layers

- Significant savings in material costs

- Sustainable response to the growing market for PVC sewage pipes

(Laatzen/Germany, September 15, 2025). Sustainability is not just skin deep – it often begins underground: in our cities' pipe systems. This also applies to the production of PVC sewage pipes. At K 2025 in Düsseldorf (October 8–15), KraussMaffei Extrusion will present a new 3-layer pipe head that allows the safe and stable processing of up to 100% recycled material. The company is thus sending a clear signal for greater resource conservation in pipe manufacturing while also meeting the growing demands of the circular economy.

Two years of development for a new standard

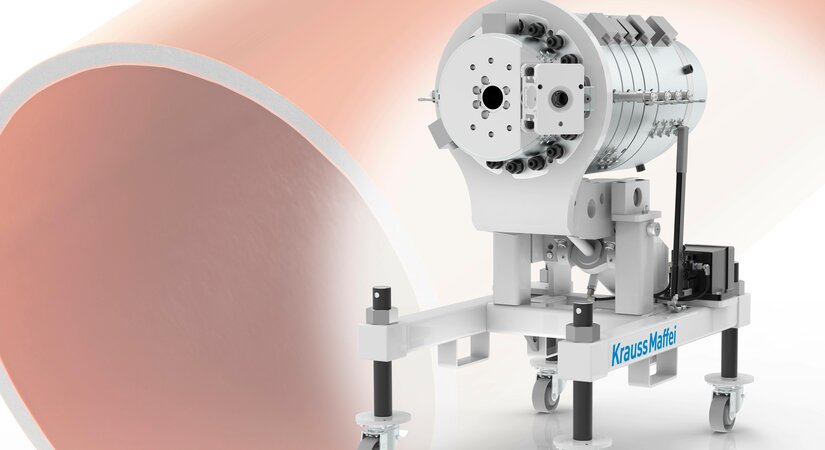

The KM-3L RK 42-HP is the result of a completely new development – not a further development of existing concepts, but a pipe head that has been redesigned and simulated from scratch. With a processing range of 400 to 1,200 kg/h and a diameter of 110 to 250 mm, it is ideally suited for large-scale industrial applications. "With the new KM-3L RK 42-HP, we are presenting the most advanced 3-layer pipe head for PVC applications. Our customers benefit from economical, sustainable, and outstanding quality pipe production," says Ralf Benack, CEO KraussMaffei Extrusion.

Intelligent design for maximum performance

At the heart of the new die head is a high-precision, patent-pending flow system with symmetrical material feed for all three layers. The solution for the core layer is particularly innovative. It benefits from a highly efficient 1-to-8 distribution, which enables extremely short dwell times and thus significantly reduces the susceptibility to errors. This allows 100 percent recycled material to be processed reliably, regardless of whether the layer is foamed or compact, and regardless of whether in-house recycled material or post-consumer waste is used.

The two cover layers are also characterized by maximum efficiency and flexibility. Currently, virgin material is predominantly used here, but the design is also suitable for the use of 100 percent recycled material.

Stable processes, big savings

The new KM-3L RK 42-HP enables manufacturers to produce much more economically. "Thanks to the largest process window on the market, long production runs with minimal downtime are possible. At the same time, material costs are significantly reduced," says Dr. Thomas Unger, Vice President Technologies at KraussMaffei Extrusion. And since material typically accounts for the largest share of operating costs, even small savings have an immediate and noticeable effect on the overall calculation.

No streaks thanks to new flow system

Spiderlines—fine, unwanted marks on the inner wall of the pipe—can be virtually eliminated thanks to the new flow system. The optimized, even material flow in the pipe head prevents material accumulation and turbulence in the pipe head, ensuring a perfect surface without streaks.

The new pipe head also does away with chrome plating and double compression entirely. Avoiding chrome plating not only reduces manufacturing costs, but also significantly improves the environmental balance. Doing away with double compression geometry reduces the thermal stress on the material, simplifies cleaning, and enables quick tool changes in everyday production.

Easy to integrate, quick to use

The new pipe head impresses not only with its technical performance, but also with its high level of maintenance and user-friendliness. Cleaning and product changes are straightforward, which in turn minimizes downtime.

With the new KM-3L RK 42-HP, KraussMaffei Extrusion demonstrates how sustainable technology and the highest quality go hand in hand. The new pipe head makes it possible to manufacture durable and reliable infrastructure products from recycled PVC while increasing cost-effectiveness.

KraussMaffei at K 2025

Hall 15, Booth C24

Contact Person

Marketing & Communication Manager Extrusion Technology

Petra Rehmet

Tel +49 5102 86088605

Mail to Petra Rehmet